Electronic devices have become the basic needs of every organization and industry in recent years. Nowadays consumers need these devices such as smartphones, laptops, and computers or maybe some medical and electrical equipment depending on the task. However, to meet the requirements of the customers and industries where advanced technologies are used, electronic manufacturing services play an important role.

Electronics Manufacturing

To make sure of the electronic product meeting the market demand. For this, the electronic manufacturing company and original design manufacturer have to work together to do thorough market research to find out if the product is in demand, and who will be the buyers of the product. They have to find out if the product is feasible or not. An Electronic manufacturing company, such as ELE PCB, does thorough analysis of the product to find what will be the time requirement to make the product or what will be the cost in manufacturing electronic devices.

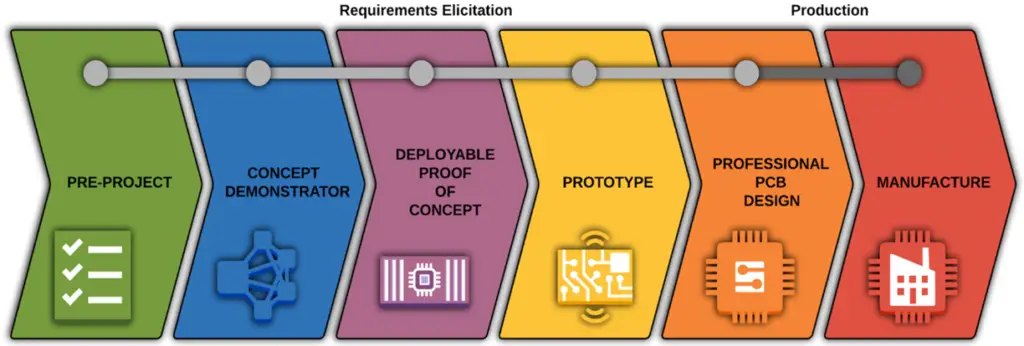

In the article, we will talk about the complete steps required for electronics manufacturing. From the concept to the design and prototype and then the final product, the important steps in electronic manufacturing are given below:

Concept of Product

The first step in electronic manufacturing is to understand and develop the concept of the product. The electronic manufacturing services need to do the problem research and the solution of the problem before manufacturing the device.

In the problem research, you have to find out the needs of the consumers, whether the product you are planning to manufacture is in demand or not, and if there is a demand what technology you will be using in electronic manufacturing.

Electronic manufacturing companies should have to use the latest technology because customers demand more compact, small, and advanced devices these days. In electronic manufacturing, you should start with a rough idea or sketch of the product. Then you should also know your target audience and you should interview them to find out what type of product they want and what their actual needs are.

After doing the research, electronic manufacturing services will be able to make their value proposition that will define the unique features of their product.

Electronic Manufacturing Process

Like Us on Facebook!

Proposal of the Product

Then in the next step after the concept of the product becomes clear, the electronic manufacturing company should be able to make their MVP also called minimal viable product which will be used throughout the process of electronic manufacturing.

Subscribe Us on YouTube!

This is also referred to as a duct tape prototype. The prototype will give the rough idea for the final device and you can have feedback by giving these MVP to their clients.

In electronics manufacturing, the MVP ensures that whether the product is feasible or not. After confirming the feasibility, the electronic manufacturing company can start making product requirement documents which will have all the information regarding the features of the product, materials that will be used in electronic manufacturing, and the purpose of the product.

Electronic Products Prototyping

After the proposal of the product and if the feedback is positive then the electronic manufacturing services start assembling the prototype. It means that now the electronic manufacturing company can produce more units of electronic devices and give them to more customers for different feedback.

In electronic manufacturing, when there is an active set of customers the electronics manufacturing service may have a rough idea of the hardware of the product as well. You can use modern techniques like 3D printing that will give you the idea of hardware in different stages of prototype.

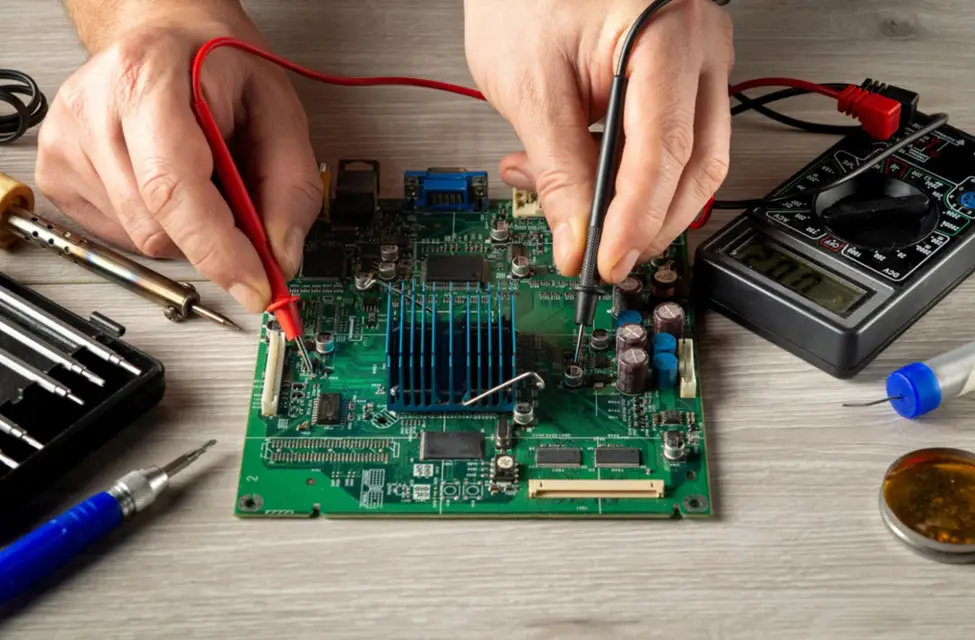

PCB Fabrication and Assembly

The assembly of PCB is the most important step in electronic manufacturing. PCB assembly involves the attachment of electronic components to the board with the help of SMT or THT technologies.

This requires the most attention as the printed circuit board directs the flow of electronic signals within the electrical device.

An Electronics manufacturing company may require PCB boards in large quantities so it may have to partner up with a manufacturer that can produce circuits and board in the required amount in a given time like FS Circuits.