Fiberglass is basically a matrix in which very fine fibers of glass exists. Fiberglass material is usually used for making of boats or for temporary sheds like sometimes on the roof tarus. That is the reason where ever the word fiber glass is touched ones always thinks of it as insulation boards or boats etc. In fiber glass a reinforced plastic-glass polymer is mixed in a polymer and if instead of that polymer one uses the portland cement and sand, then the resultant material will be known as glass fiber reinforced concrete.

What is Glass Fiber Reinforced Concrete?

GRC (Glass Reinforced Concrete) or GFRC (Glass Fiber Reinforced Concrete) basically consists of a cementitious matrix composed of cement, sand, water, and admixtures, in which short length glass fibers are dispersed. According to Bentur and Mindess1 this dispersion will lead to an increase in the tension and impact strength of the material.

Invention of Glass Fiber Reinforced Concrete

One of the Basic hurdle behind development of this Glass Fiber Reinforced Concrete was the alkaline nature of the concrete. We have discussed many times about Alkali-Silica Reaction in which the reactive silica of aggregate it reacts with the alkaline nature of the cement sand matrix. And on that note, you must also be aware of the fact that glass breaks down completely in an alkaline environment – its durability is like nothing in such an environment. However this problem was solved when Alkali-Resistant Glass (AR Glass) was developed by Owens-Corning and by nippon Electric Glass leading to a rapid increase in applications.

The idea of mixing of glass and concrete was of the fact fibers are the principle load-carrying members while the surrounding matrix keep them in the desired locations and orientations. These fibers provide reinforcement to the concrete matrix and thus provide a very useful combination of properties that cannot be achieved with either of the components alone.

Glass Fiber Reinforced Concrete was first created in 1940 by Russia but was not of the shape we used now until 1970s. Just like regular concrete, GFRC can accommodate a variety of artistic shapes. It can be etched, polished, sandblasted and stenciled.

General Benefits in Society

Glass fiber Reinforced Concrete is a material which today is making a significant contribution to the economics, to the technology and to the aesthetics of the construction industry worldwide.

It is environmental friendly composite, due to its low consumption of energy and natural raw materials formed in to a great variety of products and has won firm friends amongst designers, architects, engineers and end users for its flexible ability to meet performance, appearance and cost parameters.

Specific Technical Benefits of GFRC

There are a lot of benefits to use thin sections of GFRC (Glass Fiber Reinforced Concrete) :-

- Light Weight Construction due to thinner sections and being 75 % more light weight than similar pieces cast with traditional concrete.

- Higher Strength: can achieve upto 4000 psi flexural strength and high strength to weight ratio

- No Need of Reinforcement: As in complex shapes the reinforcement can\’t be fixed like in 3d structures than in such cases glass fiber reinforced concrete is best.

- No vibration is needed as compared to the conventional concrete

- It has high quality surface finish and no voids exists on top

- It is highly durable and sustainable concrete

- It might be more expensive initially but overall due to thin sections the cost is lesser

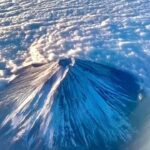

|

| The Facade of the Building with GFRC |

Casting of GFRC

Glass Fiber Reinforced Polymer Concrete can be poured or casted in the desired shapes by following three methods :-

Like Us on Facebook!

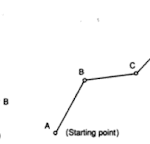

1. Spray-UP

Like shortcrete you can spray-up GFRC like a fluid in to the formwork. Using specialized guns the GFRC is sprayed.

Subscribe Us on YouTube!

2. Premix

In this case short fibers are mixed into the fluid concrete mixture and then is poured into the formwork as desired.

3. Hybrid

One final option for creating GFRC is using a hybrid method that uses an inexpensive hopper gun to apply the face coat and a handpacked or poured backer mix. A thin face (without fibers) is sprayed into the molds and the backer mix is then packed in by hand or poured in much like ordinary concrete. This is an affordable way to get started, but it is critical to carefully create both the face mix and backer mix to ensure similar consistency and makeup. This is the method that most concrete countertop makers use.