Saad Iqbal | 🗓️Modified: September 18, 2016 | ⏳Read Time: 5 min | 👁Post Views: 950

As the name suggests, no fines concrete is simply the concrete in which fines or fine aggregate is absent and omitted intentionally. Fine aggregates generally consist of natural sand or crushed stone with most particles passing through a 9.5 mm or 3/8 inch sieve.

Now you might have heard about the gradation or sieve analysis of the aggregate and you must have been told that well graded mix of aggregate is always have more strength and that is only achievable if coarse aggregates are fully enclosed and packed with fine aggregates into the spaces and interstices being developed within coarse aggregate. So from where this no-fines concrete came from?

If you are thinking about this, then your mind is a healthy one fellow, but wait a second let me answer your this question.

Sometimes there are cases where we don’t need strength or strength is not our priority, let me give you an example;

Introduction to no-fines concrete

In urban areas the most of the land is covered with Plain Cement Concrete which is only to give smooth paths and leveled ground for the persons living there. This plain cement concrete is nothing to do with the strength. But one drawback of this PCC is that it gives little or no room for the rainwater to percolate through the soil into the underground water level.

One of a very popular property and advantage of no-fines concrete is that it is the best permeable concrete ever available; as fine aggregates are absent the voids are there which allow the water to pass through the mass of the concrete easily. So if instead of that Conventional PCC we use no-fines concrete this will be very useful and helpful during rain water harvesting.

In this way the stormwater saturation could be avoided reducing the risk of flooding in heavy rain events.

Mix Design and Making of no-fines concrete

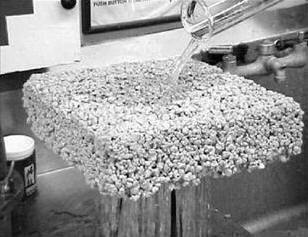

No-fine concrete is made up of only coarse aggregate, cement and water. No-fines aggregate is gaining popularity in the modern construction industry due to its advantages and benefits which cannot be achieved through conventional concrete.

In most of the cases, in no-fines concrete only single sized aggregates are used usually of size passing through 20 mm sieve and retaining of 10 mm. This single sized aggregate looks stunning in looks.

The usual proportion for mixing of cement to aggregate is 1:10 in case of heavy aggregates and 1:6 in case of light aggregates. Regarding water, actually in conventional and normal concrete water cement ratio is the standard which will decide the strength of the concrete. But in case of no-fines concrete it is the cement-aggregate ratio, water cement ratio and unit weight of the concrete.

The water should be only to cause sufficient coating of cement past around the particles of aggregates. If the water is too little it may leave loose aggregates and if too much water is introduced it will cause cement past and aggregate to segregate and flow.

Low density

Among some other features, one important feature of the no-fines concrete is lower density, it is due to the fact that absence of fines reduces the weight and it will just act like porous concrete. Reduction in weight will considerably reduces the dead load on the structure are perfectly ideal for loose soil or less bearing soil.

Low cement content needed

As we all know that surface area of fine aggregate is more than that of coarser aggregates, thus if fines aggregates were used than more cement would be needed to coat the surface of aggregate with cement, but now in this case we have this advantage that due to less – surface area low cement content is needed and thus reduced production cost.

Low thermal Conductivity

Due to the spaces and interstices between the particles and aggregates, there is considerably more isolative property for heat and thus lower thermal conductivity is observed.

No Capillary Movement

Water is famous because of its capillary action, which is caused due to the anomalous behavior of water and due to surface tension it has, the water tend to rise up with the help of fines. This phenomenon is most common in case of clay, however in case of no-fines there is no-capillary action beside sufficient permeability characteristics as already explained.

One of the widest used application of no-fines concrete is its use as backfill of retaining wall. It is ideal material for backfill.

One company called “Allan Block” is famous for its “AB no-fines concrete backfill”. They state that due to use of no-fines concrete, contractors are able to build with better production rates and with less manpower. The use of no-fines concrete backfill also eliminates the need for compaction and compaction testing of the reinforced soil. It provides superior wall drainage since the entire mass is permeable; therefore eliminating the need for wall rock in the cores and behind the retaining wall.

This pervious concrete backfill will provide “solid” solution that can reduce the overall settlement behind the wall.