Saad Iqbal | 🗓️Modified: February 21, 2017 | ⏳Read Time: 8 min | 👁Post Views: 939

Bridges in a broad spectrum is one of the major Infrastructure types that depicts the development and expansion of a region. The significance and value of a Bridge is doubt less at all. These structures have provided the ease and reduced the distances between two cities and countries. I have worked in regions full of mountains where one region is separated from the other through a vigorous river and is connected merely by means of a bridge, which; if damaged will cut off the two regions isolated and inaccessible.

|

| Parts a Bridge Structure – Concrete Span Bridge |

The

Bridge, a structure constructed to span over an obstacle like a river, canal or a roadway; is made up of several components which may not be noticed at single glance. However these components play a vital role in keeping the bridge erected and serviceable.

The following are the typical components which are present in a bridge structure;

For better understanding we have divided these components of bridge in two broad categories, as follows :-

|

| Major Parts of a Bridge Structure |

- Foundation or Sub-structure components

- Super Structure Components

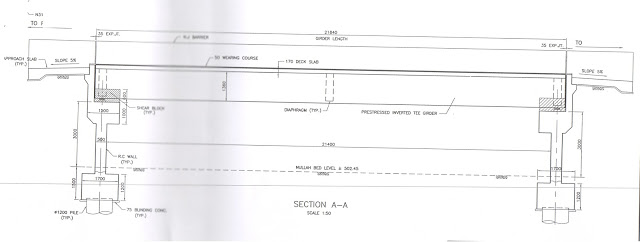

The footing of the bridge is designed to transmit the load of the vehicles or objects to the underneath bearable soil without causing any excessive settlement as well as any shear failure of the underneath soil. Usually the foundation used now days is Pile foundation as it is best suited for heavy loading and for the soils which are not that much good in terms of bearing capacity and shear modulus.

|

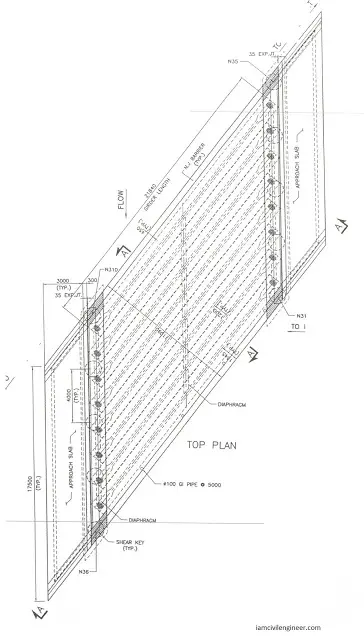

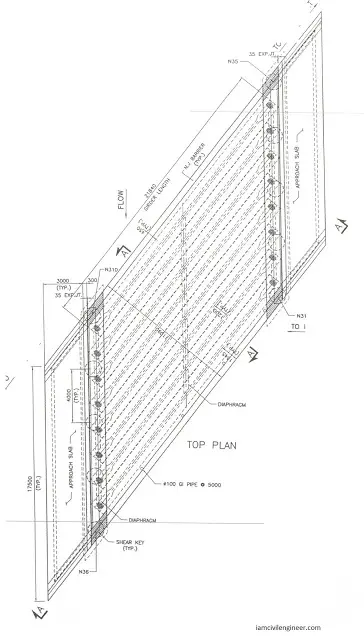

| Top Plan of a Bridge Structure [Click to enlarge] |

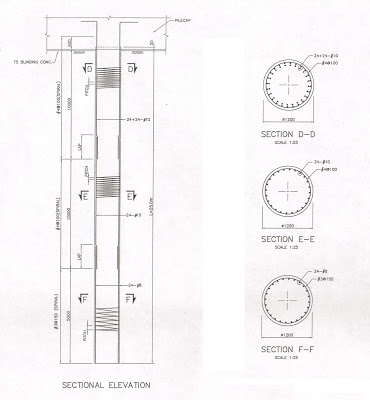

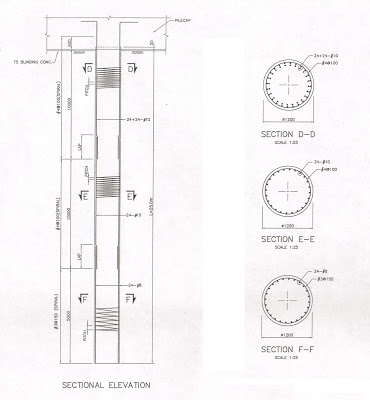

Pile

As per the definition,

pile is a long slender member that carries the load of the superstructure either through skin friction around the shaft or through end bearing to the underneath bearing stratum. A group of Piles may be around 8 to 10 at suitable spacing around 3 m upto required depth of around 25 to 35 meters can be used. In our areas usually the pile is reinforced concrete cast in-situ pile, however any type can be used it depends on the requirements based on soil condition and loading condition.

|

| Structural Details of a Pile Foundation |

Pile Cap

As it is mentioned above that certain number of piles are used thus in order to uniformly distribute the super load to the underneath piles, a reinforced concrete mat is provided called pile cap on their top which connects the piles with pier or transom (will be explained later).

Sometimes the Piles are extended directly upto the tansom without provision of pier shaft, in this case the piles needed to be of larger diameter and thus they take more space. Therefore, in congested areas and in urban areas pile cap is used which distributes the load of a transom or pier to certain no. of piles.

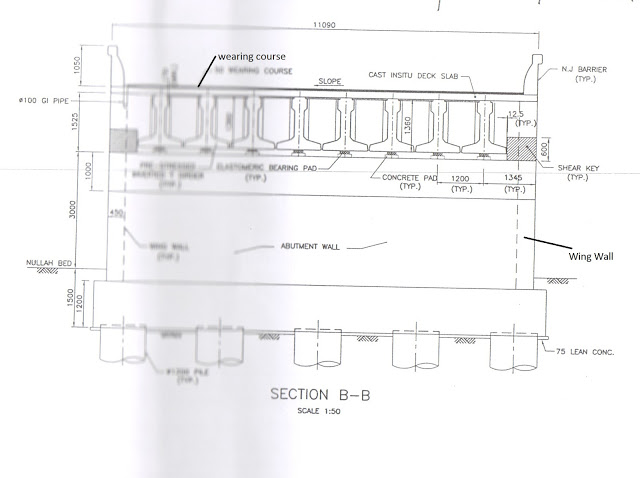

Transom

The pier projecting directly above the pile cap is like a shaft or column with small cross-sectional area which is not able to cater and take the width of the carriageway and thus they need extended dimensions in transverse direction. Thus transom is provided at the top of the pier which can be regarded as a transverse beam having concrete pad on top of which the girders are placed.

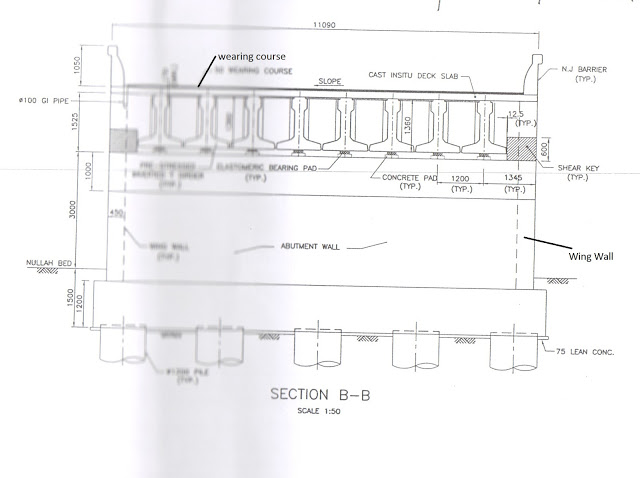

Girders Bearing Parts

Either on the abutment or on the transom of the pier, the girders are to be placed. These girders are not directly placed on the top of the transom or abutment wall. On the top of them a concrete pad may be of 100 mm thick is casted to create a stable platform for the elastomeric bearing pads to be placed.

Elastomeric Bearing pads are modern flexible bearing heavy weight rubber part that directly takes the compression load of the bridge girder. They also take care of the jerking and shocks of the girder due to movement of the girders.

|

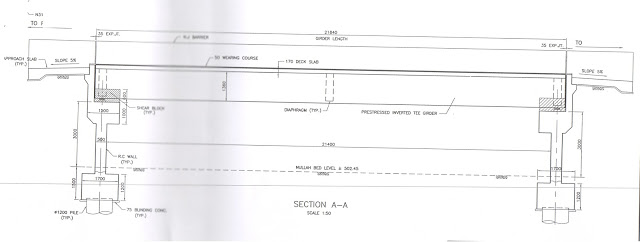

| Sectional Elevation of a Bridge Structure Showing Components |

Girders

Girders take the load of the top deck slab and transfer them to the piers or tansom or abutment. Girders usually are pre-cast that are launched by gantry cranes or any suitable safe methods; however they can be cast in place as well whatever suits. Girders can be of any shape like Inverted ‘T’ or ‘I’ Section or U Section. Depending on the width of the carriageway suitable no. of girders can be used at suitable spacing.

These girders are usually post-tensioned in order to reduce the cross-section and better to utilize the full strength of the reinforced concrete.

Diaphragm

As stated above suitable no. of girders can be used; thus these girders needed to be fixed / tied together. For this purpose diaphragm is designed; the girders have comparatively large width in zone of diaphragm; provision is present near the bottom of the girder in terms of sheaths to cross the rebar for a diaphragm of one girder to the other. In this way the diaphragm hold the girders.

Girders can have diaphragms at the center called intermediate diaphragms and also at the edges called end diaphragms.

|

| Longitudinal Section of a Bridge structure Showing Details |

Abutment

The abutment of the bridge is the structure away from the obstacle that is in transition from the height of the girder to the ground surface. The abutment of the structure consists of three components abutment wall, wing wall and approach slab.

The abutment wall and wing wall retains the fill material like sand on top of which is approach RCC slab. The abutment wall have a corbel beam on which the girders rest. The wing wall as the name suggests is in shape of Wing of an aero-plane and acts like a retaining wall to retain the earth fill material of the abutment.

In order to provide smooth transition and to take care of the stresses of the contact of the bridge with that of the ground Approach Slab is casted on the top of the earth fill material at the abutment.

Shear Key

Although this component is not that common but it is provided now a days in order to make the bridge structure safe from earthquake stresses and seismic loads. Shear keys are provided in bridge abutments so as to provide lateral restraints to the bridge givers at moderate earthquake forces.

The shear keys are designed as sacrificial which means that they are assumed not to further provide support to the structure once their capacity have been exceeded.

Deck Slab

On the top of the girders a slab is casted that might be prestressed or not. The dowels projecting from the precast girders goes into the top deck slab to have proper development so as to make a monolithic structure. The deck slab is usually cast-in-situ. The deck slab directly takes the load of the vehicles. On top of the deck slab a wearing course is provided in order to protect the bridge concrete from wear and tear and to ensure good riding quality.

N.J. Barrier

New jercy Barrier is provided on the two extreme edges of the deck slab in order to provide safety to the moving vehicles and the pedestrians crossing the bridge so they may not fall down into the spaning river or roadway.

Interesting Information About Bridges

Here are some of the interesting facts and figures you would love to know about Bridges :-

Did you know the 10 most popular bridges of the world? If not here is a list for you

- Golden Gate Bridge, San Francisco, United States

- Tower Bridge, London, England

- Sydney Harbour Bridge, Sydney, Australia

- Brooklyn Bridge, New York, United States

- Ponte Vecchio, Florence, Italy

- Rialto Bridge, Venice, Italy

- Millau Viaduct, Millau, France

- Charles Bridge, Prague, Czech Republic

- Akashi Kaikyō Bridge, Japan

- Great Belt Bridge, Denmark

Did you know about the world\’s highest bridge: Here is the answer

Duge Bridge is a cable-stayed bridge near Liupanshui in China. As of 2016, the bridge is the highest in the world with the road deck sitting over 565 metres above the Beipan River. The bridge crosses the river on the border between Yunnan and Guizhou provinces.

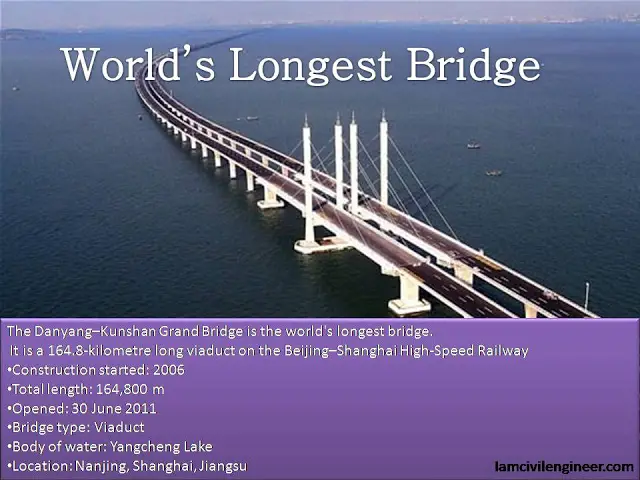

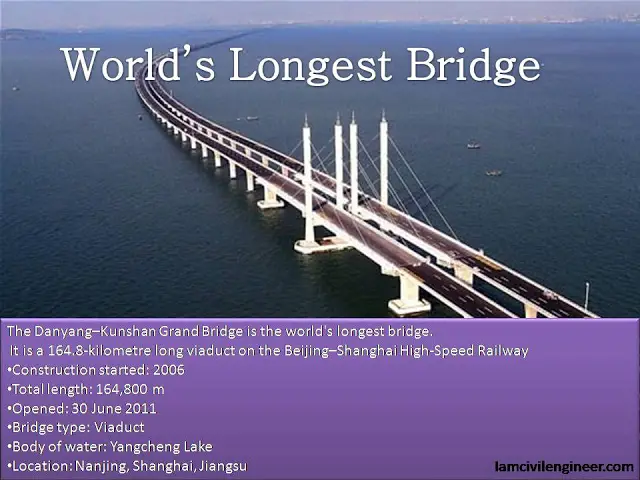

Did you know about the world\’s Longest Bridge, Here is the answer :-

The Danyang–Kunshan Grand Bridge is the world\’s longest bridge. It is a 164.8-kilometre long viaduct on the Beijing–Shanghai High-Speed Railway.

|

| World\’s longest Bridge in China |

|