Nanyang Technological University (NTU Singapore) scientists from the NTU-JTC Industrial Infrastructure Innovation Centre (I³C) have invented a new type of concrete called #ConFlexPave that is bendable yet stronger and longer lasting than regular concrete which is heavy, brittle and breaks under tension.

This innovation allows the creation of slim precast pavement slabs for quick installation, thus halving the time needed for road works and new pavements. It is also more sustainable, requiring less maintenance.

NTU Professor Chu Jian, Interim Co-Director of the NTU-JTC I³C, said, \”We developed a new type of concrete that can greatly reduce the thickness and weight of precast pavement slabs, hence enabling speedy plug-and-play installation, where new concrete slabs prepared off-site can easily replace worn out ones.\”

Mr Koh Chwee, Director, Technical Services Division of JTC and Co-Director of the NTU-JTC I3C, said that the invention of this game-changing technology will not only enable the construction industry to reduce labour intensive on-site work, enhance workers\’ safety and reduce construction time, it also benefits road users by cutting down the inconvenience caused by road resurfacing and construction works.

\”Through collaborations with universities such as NTU in research and development of disruptive technologies, JTC hopes to pioneer cutting-edge industrial infrastructure solutions to address challenges faced by Singapore and its companies such as manpower and resource constraints. We will continue to open up more of our buildings and estates to test-bed and if successful, implement such new solutions,\” Mr Koh added.

How bendable concrete works

Typical concrete comprises cement, water, gravel and sand. While this mixture makes concrete hard and strong, it does not promote flexibility. Thus concrete is brittle and prone to cracks if too much weight is applied.

ConFlexPave is specifically engineered to have certain types of hard materials mixed with polymer microfibres. The inclusion of these special synthetic fibres, besides allowing the concrete to flex and bend under tension, also enhances skid resistance.

The key breakthrough was understanding how the components of the materials interact with one another mechanically on a microscopic level, said Asst Prof Yang En-Hua from NTU\’s School of Civil and Environmental Engineering who leads this research at the NTU-JTC I³C.

Like Us on Facebook!

\”With detailed understanding, we can then deliberately select ingredients and engineer the tailoring of components, so our final material can fulfill specific requirements needed for road and pavement applications,\” explained Prof Yang.

Subscribe Us on YouTube!

\”The hard materials give a non-slip surface texture while the microfibres which are thinner than the width of a human hair, distribute the load across the whole slab, resulting in a concrete that is tough as metal and at least twice as strong as conventional concrete under bending,\” he added.

ConFlexPave has been successfully tested as tablet-sized slabs at NTU laboratories. It will be scaled up for further testing over the next three years in partnership with JTC — at suitable locations within JTC\’s industrial estates and in NTU where there will be human and vehicular traffic.

Story Source:

The above post is reprinted from materials provided by Nanyang Technological University. Note: Content may be edited for style and length.

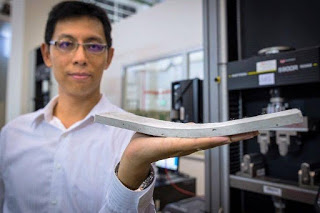

NTU Asst Prof Yang En-Hua holding the bendable concrete developed by his team.

Credit: Image courtesy of Nanyang Technological University