The construction sector frequently uses the stud welding method to attach steel studs to metal surfaces. Although stud welding is a quick and effective approach, mistakes can result in structural problems, safety hazards, and expensive repairs.

So, it’s critical to comprehend typical stud welding errors and discover how to steer clear of them. The most common stud welding errors to avoid during building construction will be covered in this article, along with advice on making solid and dependable welds.

By adhering to these recommendations, you can ensure that your building is secure and structurally strong.

Stud Welding Mistakes to Avoid While Constructing a Building

Incorrectly Positioning

When using stud welding, getting the stud in the correct position is essential for producing a solid and dependable weld.

One of the most frequent errors committed throughout the procedure, which can affect the attachment and distribution of the weight, is placing the stud in the wrong spot.

Proper positioning lowers the possibility of structural problems and increases the building’s overall strength and stability by ensuring that the load is distributed uniformly. It is crucial to follow precise placement techniques to produce a good weld and assure the building’s safety and structural integrity.

Failing To Prepare The Surface Properly

Surface preparation, which directly impacts the weld’s quality and strength, is a vital phase in the stud welding process. Surface impurities, rust, or paint can reduce the weld’s strength and longevity, creating structural problems and safety hazards.

To provide a clean, smooth surface for the weld, removing any surface impurities, rust, and paint before welding is crucial.

An effective surface preparation process guarantees that the weld has optimum adhesion and reaches the desired strength, resulting in a building that is both secure and structurally sound.

Like Us on Facebook!

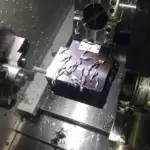

Using The Wrong Welding Equipment

The kind of equipment utilized has a significant impact on how well stud welding works. The stability and safety of the building might be jeopardized by using faulty welding equipment, which can lead to weak or incomplete welds.

Subscribe Us on YouTube!

Consequently, employing the proper stud welding tools for the particular job is crucial. Numerous stud welding equipment options are available, such as drawn arc weld studs or capacitor discharge stud welding, each with unique capabilities appropriate for particular applications.

If the right tools are used, the weld will be solid, long-lasting, and compliant with all relevant building norms and regulations.

Incorrectly Selecting The Welding Process

The correct kind of stud welding procedure must be chosen to produce a solid and trustworthy weld.

Different welding methods, such as drawn arc stud welding or capacitor discharge welding, are appropriate for particular applications and materials. However, the stability and safety of the building may be jeopardized by weak welds produced by using the incorrect welding procedure.

To ensure that the weld is strong, long-lasting, and compliant with all applicable construction norms and regulations, choosing the appropriate welding method for the particular application is crucial.

The building will be secure and structurally sound if the welding procedure is properly chosen.

Over-welding/Under-welding The Stud

Weak welds caused by either overwhelming or underwhelming the stud might jeopardize the building’s structural stability and safety. Adherence to the welding settings advised for the particular application is essential to prevent these problems.

Depending on the materials and application, welding parameters include weld time, weld current, and weld pressure change. By adhering to these guidelines, the weld will be strong and compliant with all applicable building norms and regulations.

Following the advised welding guidelines is crucial since properly welded studs produce a safe and structurally sound construction.

Not Properly Grounding The Welding Equipment

A strong, dependable weld is ensured, and electrical risks can be avoided thanks to proper grounding, which is an essential step in the stud welding process. Weak welds, reduced safety, and equipment damage can all result from the improper grounding of the welding apparatus.

By allowing the electrical current to flow properly, grounding helps to avoid short circuits and other electrical problems. Follow the manufacturer’s instructions and abide by safety regulations to guarantee correct grounding.

For a strong, dependable weld to be produced and for the stud welding process to be efficient and safe, proper grounding is required.

Failing To Inspect The Welds

An essential step in ensuring that the welds satisfy the necessary criteria is inspecting them once the welding process is finished.

Weak welds from a lack of inspection could jeopardize the building’s structural stability and safety. Weld inspection guarantees the welds are reliable, long-lasting, and compliant with all applicable building codes and regulations.

The welds are examined for flaws that can cause structural problems or safety hazards, such as cracks or porosity. Verifying the welds once the welding process is finished is necessary to maintain a safe and structurally sound construction.

Not Abiding Building Regulations And Codes

Building safety and structural integrity are protected by building codes and regulations. The integrity of the building and the safety of its residents may be compromised if these codes and laws are disregarded.

When constructing a building, adhering to all applicable norms and rules, especially those about stud welding, is crucial. This guarantees that the stud welding procedure complies with the appropriate criteria and yields a secure construction.

The building is safe and complies with all requirements of building laws and regulations are followed, which also gives one peace of mind.

Conclusion

In conclusion, stud welding is an essential step in building construction that necessitates close attention to detail to produce a structure that is both secure and safe.

Builders may ensure that their stud welding procedure produces a secure and long-lasting structure that complies with all applicable standards and laws by avoiding these errors and following best practices.