You know what, today when I rummage around

“Google Play Store” for APPs on

construction industry I got countless results with millions of thousands

downloads that made me stunned and I, although is a firm believer that

technology has had a unyielding and a rock-solid brunt on our lives, was literally amazed about it. That’s why I went out to investigate and

explore what technology has done and made our construction industry from mere concrete and steel towards an enormous, gigantic and colossal example of

technological advancement.

|

| Giza Pyramid Complex in EGYPT |

So in the next few paragraphs, you will be amazed by getting informed about some of the latest, hottest and the most modern technologies; whether it is in the machinery, equipment, gadgets, tools or whatsoever.

Like being a reality construction industry and civil engineering existed in one form or another way back with those of human beings and their history. Though it may have been primitive, there were many different projects being put up and erected from shrines and antique, primordial and ancient colossal structures, right on up to luxury homes with 4-car garages and tens of square feet of swimming pools.

While looking into history, we found that the ancient Romans were the originators to try out with concrete, mixing lime and volcanic rock to build regal and royal structures like “Pantheon in Rome”, still the largest unreinforced concrete dome in the world.

|

| “Pantheon in Rome” |

Now from having an eye on history and seeing our selves standing way ahead of them a question comes to our mind; What does the future hold for construction and technology? Will there come a day when noisy and earsplitting construction crews are replaced by swarms of automaton nanobots?

The reason for, why modern technologies have found a line of attack towards Construction industry?, exists in a hard truth, which is. Construction projects are complicated, time-consuming & resource intensive projects.

Construction Industry, nowadays is in a realm and dominion of technology, automation, computerization and mechanization. From managing every facet and aspect of a project using smartphone Digital Blueprint applications to Mapping, surveying and Monitoring the project execution at the job site with Aerial Drones; we are everywhere experiencing a hi-tech explosion in our beloved construction industry.

This steady onslaught of technological wizardry has revolutionized how the project managers take control on the budges expenses, take control of the risk factors, monitor the safety and environment of the project, crashing the activities for on-time completion, allocating and employing resources in an efficient, well-organized and professional manner.

Construction manager Office Without File Rack ! Thanks to Blueprint Applications

When I was, in my life, first time at site; I was given the task to manage drawings of the projects; keep tracking of the changes from previous revisions and then to distribute the drawings to the concerned individuals along with updating the log and a master file; which was as bulky as my weight, lolz.

|

| Thanks to Blueprint Applications |

Gone are these days of having bulky registers and site offices overflowing with documents, correspondences and records – Now you only need an application-ridden tablet or a phone having softwares like Rollout, Procore, Aconex etc; thanks to the sheet management, Intelligent Markups and Social Collaboration of these applications you have the bulky drawings in your light weight champion you can call heavy-weight champion.

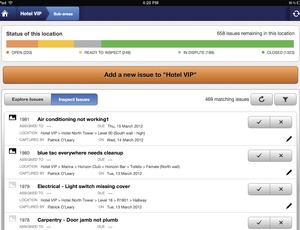

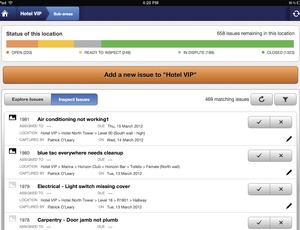

With the Blueprint Apps like PlanGrid, FieldWire, SmartDraw, Floor Plan, Defectradar and countless others; you can easily share plans, markup photos and reports with the entire project team as and when it matters. You can track revisions, document progress, and manage issues in the field while keeping everyone on the current set.

|

| PlanGrid, FieldWire, SmartDraw |

Possible obstacles can be accounted for and tweaked before beginning physical work and then having to change them (usually at great cost) due to an oversight. These apps allow for direct communication, in real time, between the owner, project managers, and other staff, so everyone is kept in the loop, 24 hours a day.

Drones – Let them take the heat of Sun for you while sitting on your Air Conditioned Chair

Way back years ago when I was working on a highway project of an interchange; I was amazed to look the project progress by matching the new Google Maps picture with that of the old one before the start of project and thought how amazing it would be if somehow everyday Google Map can update the picture; thanks to the Drone Technology the next big technological boom of the era.

|

| Drone Technology the next big technological boom of the era. |

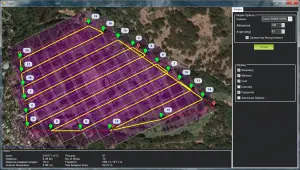

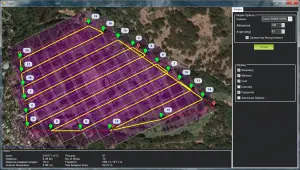

The Drone Aerial Intelligence system helps construction companies to capture progress and conduct site surveys on the job site. These drones can generate high-resolution aerial images along with topographic maps, 2D and 3D models, and accurate volumetric data.

With these drones you can get immediate reliable data for project estimation moreover civil survey designs and construction stakeouts make it a golden sparrow of any construction project. If you are a project manager than 90% of your work can be done by a drone by providing most up to date reporting, tracking resources and optimizing your budget and time.

These drones can work on all sorts of projects whether you are building a dam or rebuilding your home or even remodeling it. From scoping out the big picture above to drastically improving safety and efficiency in your business, drones are a great way to make sure that your construction projects is the best it can be.

|

| improving safety and efficiency in your business, |

You can use drones to quickly survey your job site and build maps. Instead of using human resources, heavy machinery & expensive surveying tools, that produce complex data, you can get the job done in half the time & money with greater accuracy.

The data from drone is then used in a process called GIS mapping, which creates a digital map through a mix of statistical analysis and cartography. These maps have a very high definition and allow for the viewing of very specific information about an area that’s easy for the manager to access.

DSMs or “Digital Surface Models” show the dark blue areas that need most focus on them. Like areas where the dike sometimes need to drain. Companies like Kespry, Brassfield and Gorrie claim to have technologies that provide fulfillment for a project and construction manager;

GPS in construction Industry – How Satellites have Helped you? !!!

GPS is a short acronym of Global Positioning System. It is a network of orbiting satellites that send precise details of their position in space back to earth. The signals are obtained by GPS receivers, such as navigation devices and are used to calculate the exact position, speed and time at the vehicles locations.

After its first launch in 1988 it has revolutionized the navigation as well as the survey work of the construction industry. GPS can be used for many tasks in construction surveying such as measuring the grading, elevation, staking, mapping and site exploration. Construction surveying is a process that collects data, which helps in planning a perfect construction project without any possibility of construction flaws. Now you don’t have to opt the traditional electro-optical-mechanical devices to survey the area like measuring tapes, compasses, levels and similar devices.

|

| GPS surveying instrument receives signals from GPS satellites |

GPS surveying instruments offer measurements in 3d (X, Y and Z) planes that make it easy for the surveyor to take precise measurements for any point of the area. The GPS surveying instrument receives signals from GPS satellites in terms of longitude, latitude and elevation (from sea level) along with some other information that helps the GPS surveying instrument display exact measurement.

GPS have transfigure and modernize the traditional hectic survey work. You can now do survey in just 5 mins; you have the freedom to work in any weather and in any place. Companies like Leica geosystems have equipments that can perform Topographical tasks, Hemisphere GPS, Geological mapping.

Computer Aided Design (CAD) – the Evergreen Modernization in the Construction Industry

CAD has enabled construction to begin before the design is fully complete, allowing for

fast-track construction and reduced interferences . It improves procurement and performance systems, allowing a host of possible issues to be tackled before physical work begins, significantly reducing the risk of errors and thus reducing the risk of going off-budget or off-schedule.

CAD has resulted in several major changes in construction technology, such as the move toward engineering workstations that are dedicated to the CAD process. CAD systems can store large numbers of civil, structural, and electrical schematics. Furthermore, compatible solutions to integrate into CAD software have emerged and continue to be updated.

3d printers and construction industry

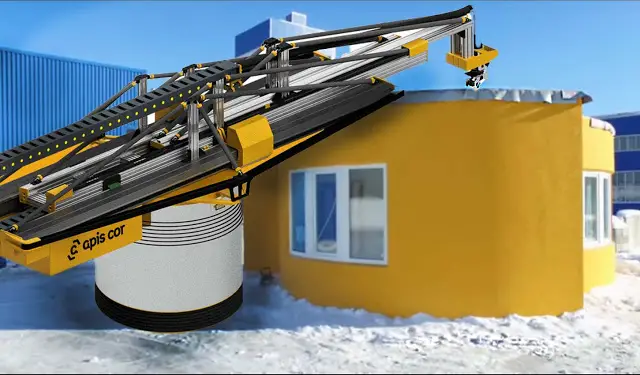

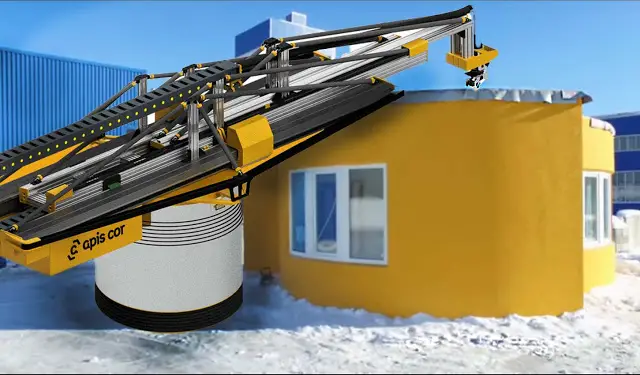

This innovation is a recent modernism that has taken the construction industry with a gigantic hammer surprise; while printing our CV with a HP LaserJet one can’t ever have imagined that one day a 3D printer might be printing the house we would be living in. 3D printing is changing the construction industry before our eyes. Inventor of 3d printed house was Ma Yihe, in Shanghai, China, 2014 before that nobody could have envisaged that one day we could really print a house when 3d printing was in its infancy.

|

| Apis Cor Constructed this house with Drone Technology in 24 hours |

3d printing will dramatically reduce the cost of housing, and increase the speed of construction. 3D printing – driven innovation in construction will empower people by creating more disposable income for homeowners and generally improve the quality of life.

Most well known 3d printing construction firm is WinSun Global, based in China. They first revealed their plans to build 3d printed houses in 2014. The company uses a 22-foot tall industrial 3d printer to create houses in under 24 hours. The first construction was models, apartment-sized spaces building by combining separate rooms. Since than winsun has branched out to take on much bigger project. Other companies include Qingdao Unique, Shanska, a uk contracting company, WASP, MX3d and Apis Cor. From all the parts of the world humans are now witnessing 3d printed houses, apartments, plazas and even bridges.

3d printed soil – Future replacement of Construction Material

At the institute for Advanced Architecture of Catalonia (IAAC), S. Giannakopoulos has designed a printer that can utilize the natural soil along with few additives and print a soil that can be used a building material with tensile strength 3 times more than industrial clay.

Soil can be recycled an indefinite number of times over an extremely long period. While keeping the availability of the soil everywhere this might be in future prove to be life saving technology for the deprived people of the backward areas not having much economic power to develop concrete and other construction materials.

Transparent Aluminum – The future for the Clear Crystal Glass

For decades, chemical engineers have dreamed of a material that combines the strength and durability of metal with the crystal-clear purity of glass. Such a “Clear metal” could be used to construct towering glass-walled skyscrapers that require less integral support.

Secure military building could install thin transparent metal windows impervious to highest caliber artillery fire. Aluminum power is placed under immense pressure, heated for days at 2000 degree and finally polished to produce a perfectly clear, glass like material with strength of aluminum called alon.

|

| Transparent |Aluminum – The Future of Glass Industry |

This innovative Aluminum has already being used by many Military departments for making secure buildings and secret hideouts.

Self – Draining Roads – permeable concrete – a New Innovation

Pervious concrete pavement is a unique and effective means to address important environmental issues and support green, sustainable growth. By Capturing storm water and allowing it to seep into the ground, porous concrete is instrumental in recharging groundwater, reducing storm water runoff.

In pervious-concrete, carefully controlled amounts of water and cementations materials are used to create a paste that forms a thick coating around aggregate particles. A pervious concrete mixture contains a little or no sand, creating a substantial void content. Using sufficient past to coat and bind the aggregate particles together creates a system of high permeable, interconnected voids that drains quickly.

While pervious concrete can be used for a surprising number of applications, its primary use is in pavement.

Self charging roads – Highways having LIFE!!!

Britain Government is getting ready to test out the first ever road technology that would allow the hybrid and electric cars to get recharged without having frequent stops. Most electric cars get charged via plug-in chargers at home or while parked on the streets.

These new charging roads work on the principle of magnetic induction technology that would allow them to get charged wirelessly. Cables buried underneath the highway would generate electromagnetic fields that could be picked up by a receiver in the car and transformed into electric power.

|

| Self Charging Highway Lanes in UK – An innovation Technology |

Self-cleaning roads – Clean and Clear !!!

Self Cleaning Road Material is being researched by the University of Eindhoven in the Netherlands that would resulted in a 25 to 45 % decrease in NOx in the air – which is a good thing. NOx gets gripped by the Titanium Dioxide baked into the Pavement, a photo catalytic material that uses sunlight to convert the NOx to nitrate, which is then washed away by rain. The road material also breaks down algae and dirt.

Self Healing Concrete – Zero Cracks is the Best Policy !!!

Hendrik Jonkers have produced this concrete which he called as “bio-concrete” that “Self-heal” by producing limestone that repairs and fills the gap of cracks generated. The bacteria which he uses are form the family of Bacillus psedofirmus which is found naturally in highly alkaline lakes near volcanoes, and are able to survive for up to a staggering 200 years without oxygen or food. They are activated once they come in contact with water and then use the calcium lactate as a food source, producing limestone that as a result, closes up the cracks.

All of these construction technology innovations lead me to one question: with this phenomenal growth trajectory, set alight by technological ingenuity growing by the day, where could we be and what could we create in the next 100 years?

There is no doubt about it: the future is bright, and the future is mobile. Technology has brought the industry speeding into the 21st century.

More?

What do you think will happen? Did I miss something? Leave your thoughts

Regards for this grand post, I am glad I noticed this website on yahoo.

Regards for this grand post, I am glad I noticed this website on yahoo.