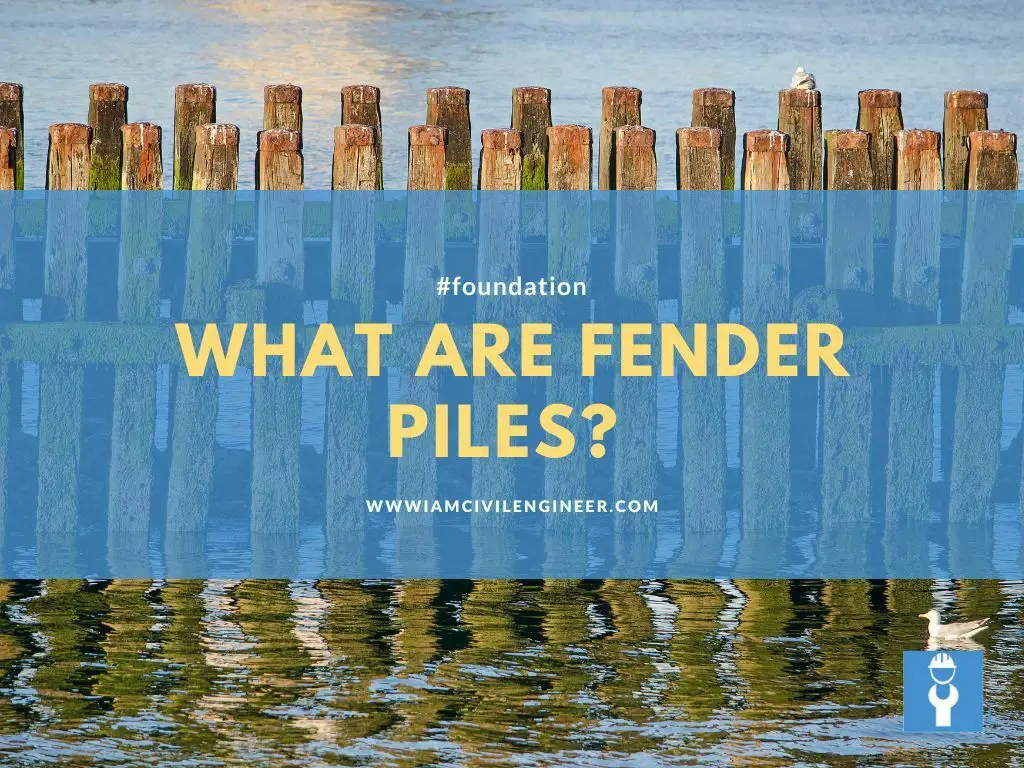

Ever wondered what fender piles are and why they’re used in construction? Fender piles are large vertical members driven into the ground next to the ship and they protect the dock or ship’s wharf from the vessel’s collision. Pre-stressed concrete Fender Piles are the material of choice for preventing collisions between fixed piers and boats.

In this article we’ll explain everything you need to know about fender piles and how they can benefit your project!

What is fender piles?

The piles used to protect concrete deck or other water front structures from the abrasion or impact that may be caused from the ships or barges (when they are tied up at the desk), are called fender piles. The fender piles are originally made up to timber.

Sometimes a man-made marine structure is made that extends out from the water level, termed as dolphin is also used to protect structures from the possible impact by ships. These are constructed by driving piles in a line and are connected above water level.

Fender piles can be of wood, steel or concrete depending on the design criteria. In case of concrete piles the prestressing can also be used to increase the fending capacity. Timber fender piles are less expensive initially than the steel fender piles and also require less long-term maintenance.

Uses of fender piles?

Fender piles has number applications including, protecting concrete decks or other waterfront structures from the abrasion or impact caused by ships.

Fender piles are often confused with anchor piles; however both are different structures with different sets of applications. Anchor piles are used for anchoring sheet piles to provide horizontal resistance for sheet pile walls. Whereas, fender piles protect decks and structures from impact of ships or other structures.

The collision between ships and platforms or other installations in offshore oil and gas fields is a type of accident which can have catastrophic effects, and as such is a cause of growing concern. That’s why it is critical to use fender piles to protect your project and structures.

Advantages and disadvantages of fender piles

Fender piles when closely spaced provide good protection for berths in large tidal ranges, especially where small vessels are to be accommodated. However, they require suitable geotechnical conditions. Moreover, the replacement of damaged piles in front of berth usually necessitates temporary restrictions on berth usage.

Like Us on Facebook!

Types of fender piles

Here’re some common types of fender piles used in marine and offshore structures:

Subscribe Us on YouTube!

- Hollow cylindrical (diametrically loaded) fenders

- Cylindrical floating (diametrically loaded) fenders

- V-shaped fenders

- Buckling column fenders

- Rectangular or square section solid strips and D bore fenders

- Fender piles

- Floating pneumatic fenders

- Foam filled floating fenders

- Fixed pneumatic fenders

Timber or wood fender piles

Wharf Timber pile

This is a system that employs piles driven along the bottom of the wharf. There are wales and chocks that can be used to support piles lateraly or fix them in various patterns in response to tidal variations and pile length. Wales can be used singly or multiple-row based on pile length and tidal variations.

Fender piles absorb impact energy through the fender’s deflection, and the pile’s limited compression increases the energy-absorption capacity, which is related to the length, peneration and material of the pile. The energy-absorption capacity is determined by the pile’s internal strain characteristics.

Pros: The advantages are low initial cost and abundant timber piles.

Cons: The disadvantages include

- limited energy-absorption capacity that declines as a result of biodeterioration;

- susceptibility to mechanical damage and biological deterioration;

- High maintenance cost if damage and deterioration is significant.

Hung timber piles

This system consists of timber members fastened rigidly to the face of a dock.A contact frame is formed that distributes impact loads.

Advantages.The advantages are very low initial cost and less biodeterioration hazard.

Disadvantages.The disadvantages are low energy-absorption capacity and unsuitability for locations with significant tide and current effects.

Steel pile

Steel fender piles are occasionally used in water depths greater than 40 feet or for locations where very high strength is required.

Advantages. The advantages are high strength and feasibility for difficult seafloor conditions.

Disadvantages. The disadvantages are vulnerability to corrosion and high cost.

Concrete pile

Reinforced concrete piles are not satisfactory because of their limited internal strain-energy capacity.Prestressed concrete piles with rubber buffers at deck level have been used.

The advantages is that this pile resists natural and biological deterioration.

Disadvantages.The disadvantages are limited strain-energy capacity and corrosion of steel reinforcement through cracks.