Saad Iqbal | 🗓️Modified: December 13, 2016 | ⏳Read Time: 7 min | 👁Post Views: 1549

Provision of reinforcement in concrete, we all know, is due to its tension carrying capability which can be utilized completely provided the bond between the steel reinforcement and concrete is up-to-the-mark and does not lack any required friction and anchorage. However this bond may fail in certain situations which is disastrous and fatal, thus in order to avoid we must find some alternatives and with safety factor we can minimize and may completely eliminate chances of failure.

It is usually observed in Reinforced concrete structures that if the reinforcement has sufficient quantity of concrete surrounding along with large concrete cover and bar spacing the failure of bond usually occurs by direct pullout of reinforcing bar. On the other hand, in contrast, insufficient cover and confinement leads to bond failure by splitting of concrete.

The anchorage and holding power of concrete for reinforcement can be enhanced by providing development length and end hooks if required. In this post we will look forward only towards development, What development length is? How it can be calculated and How it reduces the risks of bond and anchorage failure.

Before going into the details lets discuss some important points and literature review about the bond strength between reinforcement and the concrete;

Discussion about Development Length

In the modern reinforced concrete works, the rebars used are usually of deformed shape with ribs in perpendicular or inclined directions depending on the brand and factory standards, purpose of these ribs is to provide mechanical interlock with the concrete which, now a days is more important than the adhesion and frictional resistance.

The reinforcement provided in a structural element of a building like a beam; is subjected to bond forces acting on reinforcing bars. These forces are caused due to flexural and shear stresses within the member. These bond forces and stresses might result in the sliding of the steel relative to the concrete provided the pullout resistance has overcome and splitting has spread all the way to the end of the rebar which would lead to immediate collapse of the structure.

The bond failure immediately adjacent to the cracks will often occur at loads considerably below the failure load of the beam. These local failures result in small local slips and some widening of cracks and increase of deflections, but will be harmless as long as failure does not propagate all along the bar, with resultant total slip.

If the end anchorage of the rebar is reliable such failures can be avoided; these end anchorage can be provided by hooks or by extending the straight rebar a sufficient distance from the point of maximum stress.

Definition of Development Length

Based on above discussion we are now able to define what is development and why the rebar needs to be developed along certain sufficient length.

Development length is defined as the embedment length necessary to develop the full tensile strength of the bar, controlled by either pullout or splitting and thus avoiding any bond failure within the member.

Example of Development Length

Now let us consider an example to better understand the meaning of development length ;-

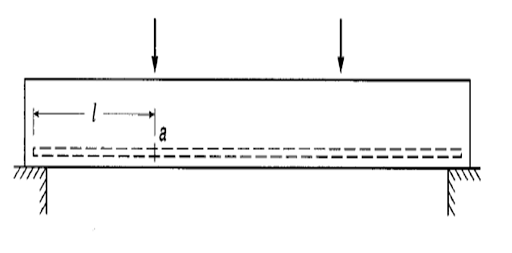

In the above figure a simple beam is shown of a certain length with two vertical forces / loads at locations as shown; it is obvious from the diagram that while neglecting the self weight of the beam, the stressed would be maximum at point a on the rebar as shown.

If the stress on rebar at a is taken as fs, than the total tension force would be Ab fs where Ab is the area of beam and fs is the stress in steel. This total tensile force must be transferred from the bar to the concrete in the distance l by bond forces. This length l must be equal to or greater than the development length of the rebar as per its diameter in order to avoid premature bond failure.

Factors Affecting Development Length

There are both simplified and comprehensive equations out there in the literature to calculate and find out the development for a certain situation. Based on this here is a summary of the factors as given in ACI code for the development length.

1. Compressive Strength of the Concrete : – the development length required for a rebar is inversely related to the compressive strength of the concrete which means if more is the compressive strength than less would be the required development length.

2. Density of the concrete (Light weight or normal weight) : For light weight concretes, the tensile strength is usually less than for normal density concrete having same compressive strength; accordingly, if lightweight concrete is used, development lengths must be increased.

3. Rebar Clear Cover : Clearly, if the vertical or horizontal cover is increased, more concrete is available to resist the tension resulting from the wedging effect of the deformed bars, resisting to splitting is improved, and development length is less.

4. Rebar Center to Center Spacing: if the rebar spacing is increased than more concrete will be available per rebar to resist horizontal splitting. In Beams, bars are typically spaced about one or two bar diameters apart. On the other hand, for slabs, footings, and certain other types of member, bar spacings are typically higher and thus required development length is less.

5. Transverse Reinforcement : Transverse reinforcement like that of shear stirrups improves the resistance of tensile bars to both vertical and horizontal failures because the tensile force in the transverse steel tends to prevent the opening of the crack Thus if the transverse reinforcement is present the development length required would be much less.

6. Vertical location of the horizontal rebar : It has been observed that if excess fresh concrete is casted below a rebar of more than 12 inches than there is a tendency for excess water, often used in the mix for workability, and for entrapped air to rise to the top of the concrete during consolidation and resultantly reduced bond strength. Thus more development length is required in such cases.

7. Coating of rebar : Sometimes in some projects where the structure is subjected to corrosive environmental conditions or deicing chemicals epoxy coated rebars are used instead of normal rebar. Studies have shown that in such cases the bond strength is reduced and thus more development length is required.

8. Rebar Diameter : most important and common factor that would influence the development length is the diameter of the reinforcement used. It has been observed that smaller diameter bars require lower development length than that of the larger diameter rebar.

I hope after reading this article you are now able to fully understand the definition of development length, the requirement of development length and the factors of the development length. In some future articles we would be discussing on how to calculate the development length with ACI Equations, so stay tuned and Happy Civil Engineering.