What Is The Difference Between Lap Splice Development And Anchorage Length

Reinforced cement concrete is the widest used construction material in civil engineering whether it is that of dam, highway bridges, buildings or infrastructures. Reinforcement used along with concrete proves to be the best available material in terms of economy, strength and sustainability. Choice of reinforcement within a structural member is due to countless advantages and benefits.

The question asked in the title is among those common confusions that exists between professional practicing engineers and site managers. Thus, here we are providing you the article to remove such confusion.

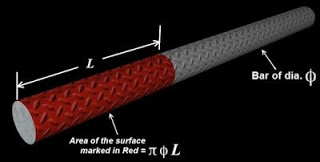

In order to subject the steel reinforcement to ultimate stress especially in tension, we need to make sure that it is firmly fixed at both ends and doesn’t slip out. Absence of such an arrangement would result in stress concentration in steel, cracks in concrete and even failure of the member.

Development length anchorage and lap length serve the same purpose but in different situations. Their main function is to provide sufficient bond strength between the reinforcement and concrete.

Lap Length addresses the length of the bar needed to transfer the stresses to the other bar whereas development length addresses the length of the bar needed to transfer the stresses to the concrete.

Lap length is different in case of tension and compression zones and mainly depends on grade of concrete and steel.

If two different dia bars are to be lapped, lap length is based on smaller dia.

The values of the development length and that of splice length is that for uncoated reinforcement and of normal weight concrete.

If the rebars are bundled than the following multipliers shall be applied to the values in above given table.

a) 3-Bar bundles in Tension or Compression = 1.20 x Table values

b) 4 – Bar Bundles in Tension or Compression = 1.33 x Table values

c) Lap splices for each bar in a bundle shall be staggered. Entire bundles shall not be lap spliced.

Similarly in the table there are words used “Top bars” and “other Bars” so here is a definition for these terms :-

Top bars are horizontal bars in the top face / layers (s) of beams and slabs, so placed that more than 300 mm of fresh concrete is cast below the bar being developed or spliced.

All other horizontal and vertical bars in beams, slabs and walls shall be classified as other bars, unless otherwise noted on the drawings.

Laps or Lap splices are usually needed in following two situations :-

1) A long rebar more than 12 m is to be provided in such a case two bars of required length are lap spliced.

2) The rebar is changing its shape or direction in a way that there is no possibility for a single rebar to complete the shape as required by the structure.

In Ideal situations these lap splices and laps are to be avoided and must be single rebar as these zones are vulnerable for having less strength as that of the single rebar. Therefore, Lap splices shall not be used in locations of maximum moments unless otherwise permitted on the construction drawings.

Classes of Splices

The values as given in the table are considered as class ‘B’ splice for class ‘A’ splice

Splice length = 0.77 x Table value but not less than 300 mm.

When rebars of different diameters are lap splices, splice length shall be larger of :-

Development length of larger bar and splice length of smaller bar.

As per the standard; “the calculated tension or compression in any bar at any section shall be developed on each side of the section by an appropriate development length or by end anchorage or by a combination thereof.

Anchorage length is provided if sufficient development length cannot be able to be provided inside the support/fixed end. L value is generally considered as 8 times dia for a 90 degree bend while 6 times dia for a 135 degree bend and 4 times dia of bar for a 180 degree bend. In most all cases, we use 90 degree bend.

We need to check for the development length in cases for tension reinforcement at supports of continuous beams and cantilever supports.