TMB is used as an alternative to drilling and blasting (DB) methods. TBMs are used to excavate tunnels with a circular cross section through a variety of subterranean matter; hard rock, sand or almost anything in between.

As the TBM moves forward, the round cutter heads cut into the tunnel face and splits off large chunks of rock. the cutter head carves a smooth round hole through the rock — the exact shape of a tunnel. Conveyor belts carry the rock shavings through the TBM and out the back of the machine to a dumpster.

Tunnel lining is the wall of the tunnel. It consists of precast concrete segments that form rings, cast in-situ concrete lining using formwork or shotcrete lining.

A tunnel boring machine (TBM), also known as a \”mole\”, is a machine used to excavate tunnels with a circular cross section through a variety of soil and rock strata. They may also be used for microtunneling.

They can bore through anything from hard rock to sand. Tunnel diameters can range from a metre (done with micro-TBMs) to 19.25 metres to date. Tunnels of less than a metre or so in diameter are typically done using trenchless construction methods or horizontal directional drilling rather than TBMs.

TBM excavate tunnels with circular c/s through a variety of geological conditions.

Tunnel diameter can range from 1- 15 m.

One of the first TBM built was used for the construction of Hoosac tunnel- Railroad tunnel in the Northern Berkshire towns of Florida and North Adams Constructed of cast iron, it managed to drill 10 feet before breaking down.

BMs are preferred in urban tunneling and underground mining over conventional methods.

ADVANTAGES OF TBM

- Reduced disturbance to the surrounding soil

- Produce a smooth tunnel wall reducing ventilation requirements

- Reduce cost of lining

- Improved personnel safety

- Working speed- 6 times greater

- Hence, wherever speed and safety becomes the main criteria, use of TBM despite its heavy capital cost is preferred.

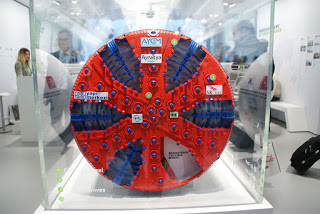

MACHINE PARTS

A TBM typically consist of

Cutter head

Shield –metal cylinder serving as temporary support

structure while excavation

Trailing support mechanisms

• Precast concrete segment handling & installing devices

• Conveyor belt system for muck removal

• Control Cabin

• Supply tanks, exhaust fans etc.

TYPES OF TBM

Based on no. of shields used

1.Main beam TBM

2.Single shield TBM

3.Double shield TBM

Based on the face supporting technique used

1.Earth pressure balance TBM

2.Bentonite slurry TBM

3.Compressed air TBM

4.Fluid balance TBM

[youtube https://www.youtube.com/watch?v=MuYdnzcQXhk]

[googleapps domain=\”drive\” dir=\”file/d/0B5oarfYUwEDra3hhbHFMT1F1Mk0/preview\” query=\”\” width=\”640\” height=\”480\” /]Download this PPT