Have you ever wondered how bridges hold up so many cars and trucks?

Bridges can be small and simple to big and meticulously engineered. Structural engineers have designed different kinds of bridges throughout the centuries, and they all serve the same purpose: they allow people to get from point A to point B.

Three main forces

The stability of a bridge is contingent on the balance of three main forces: tension, compression, and load. When this balance is achieved, it stays locked in place. While bridges may be designed top-down, they’re built from the ground up.

Construction starts with the bridge’s foundations. This usually consists of a set of piles, allowing the forces transmitted through the bridge to be evenly distributed to the ground below.

A tier above, there’s the substructure, usually comprised of abutments at the bridge’s ends and piers right above the bridge’s piles. Then we have the superstructure, consisting of the deck and other structures in place to help tie the whole bridge together.

These fundamental traits allow bridges to function effectively regardless of their design.

What makes bridges so strong?

Excellent question!

Sometimes, when a road or railroad track needs to go across something big like a river or a deep valley, experts called engineers design and build bridges to do that job.

Bridges can be really busy. Take, for example, what’s said to be the world’s busiest bridge: the George Washington Bridge in New York City.

Like Us on Facebook!

Look at all those cars and trucks!

Subscribe Us on YouTube!

It has to be pretty sturdy to carry so many people in cars.

For a bridge to carry that much weight, it has to be built from special materials like iron and steel. But it takes more than tough materials to make a strong bridge. So, let’s look at how bridges work.

Beam Bridges

One very simple kind of bridge is called a beam bridge. When we say simple, we really do mean simple. A beam bridge can be just a log that you use to walk across a stream or a long strip of cardboard placed between two short blocks. That’s a beam bridge too.

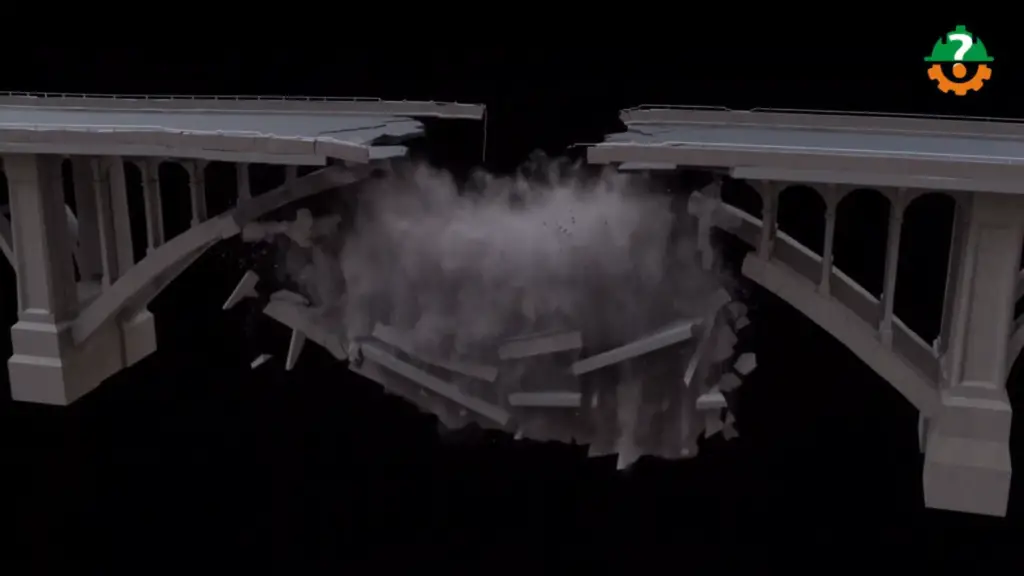

All bridges can hold a certain amount of weight, but what happens if we put too much weight on a beam bridge?

Let’s find out.

It collapses!

So, a bridge that carries trucks and cars, which are very heavy, would have to be stronger than a bridge that carries bikes or people on foot, which are lighter.

Stronger Bridge Designs

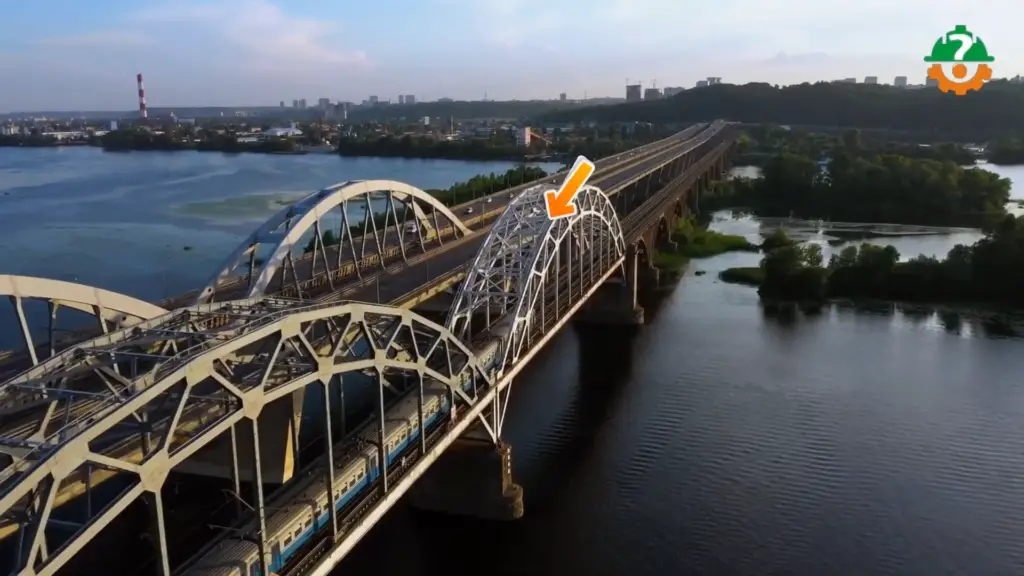

So, how do we make stronger bridges? Over time, people have learned that certain shapes can be used to make stronger bridges. Take a look at this railroad bridge. It has to be strong because it carries trains. What shape do you see?

That’s right, triangles!

And that’s not by accident. The fact is, triangles are really strong shapes for building. If you put force on one side of a triangle, it bends. But if you put force on its point, it keeps its shape.

That’s because the two sides of the triangle are pushed down by the force, and the bottom gets stretched out to both sides. Each side feels the force, but none of them bends. This makes the triangle a really sturdy and stable shape.

This is why you’ll see lots of triangles in bridges, both above the part that you actually travel on, called the deck, and below it. The long string of triangles that you see in a bridge is called a truss. Trusses help a bridge spread out the weight that it has to carry.

Suspension Bridges

But not all bridges are made of trusses. If a bridge has to cross a really wide body of water, it might be too difficult or expensive to build a truss bridge.

So, engineers design another kind of bridge called a suspension bridge. The Golden Gate Bridge in California is a great example of a suspension bridge.

Suspension bridges work by using a force called tension. Tension is just pulling something tight. Suspension bridges are made of a deck that’s hung or suspended from thick cables that stretch from one side of the bridge to the other. These cables are supported by tall towers and then are held down tightly, or anchored, on both ends.

Suspension bridges are strong because the force on the bridge gets spread out.

The weight of the cars, trains, or horses—whatever is traveling across it—pulls on the cables, creating tension. Those cables then pull down on the towers and also pull on the anchors on either end of the bridge to hold up the deck.

Different Types of Bridges

Why do bridges come in so many different shapes and sizes? Different situations call for different types of bridges.

Arch Bridges

Arch bridges have been built for millennia and for good reason. They are relatively cheap and easy to construct. Historically, they have been made from natural materials such as stone and brick, yet they are incredibly strong.

Their iconic arch evenly disperses the load across instead of down, transferring the load to the base of the arch, which functions as a strong pair of abutments.

Nowadays, materials like steel and pre-stressed concrete make it possible to build longer arch bridges, even over deep gorges such as the New River Gorge, where the roadway is 876 feet high and 3030 feet long.

Beam Bridges

Beam bridges feature an even simpler design. Fundamentally, they consist of horizontal beams supported by a series of piers. Their strength mostly depends on the distance between each pier, so they rarely have individual spans of more than 250 feet across.

However, some beam bridges are far longer than this, such as the U-Bein Bridge. This bridge has 482 spans totaling 0.75 miles in length and was originally constructed entirely of teakwood, making it the longest teakwood bridge in the world.

Truss Bridges

Truss bridges can be thought of as slightly more sophisticated beam bridges. They feature a series of triangular-shaped supports between the horizontal beam and the piers, allowing them to handle a high load over large distances.

Due to the simplicity of their design, some truss bridges can even be assembled on-site with prefabricated parts by a team with no special equipment, such as the Bailey Bridge.

Cantilever Bridges

The first cantilever bridge, built in 1867, was seen as a major breakthrough. It works by using cantilevers, which are horizontal structures supported only on one end.

It sounds a little dangerous, but it’s extremely safe and secure. If a gap is too wide to be spanned by one cantilever on each side, a beam or truss bridge is often placed between the arms of the two cantilevers, connecting them into one suspended span bridge.

One big advantage cantilevers have over other bridge types is the efficiency of their construction; they don’t need temporary structures to support their foundation. An iconic example of this is the Golden Gate Bridge.

Suspension Bridges

Suspension bridges are used for long crossings, with lengths spanning up to 7000 feet. They are also used in places where there isn’t a stable enough foundation for arch bridges.

In suspension bridges, the piers on the north and south ends are connected by draping main cables, which are attached to the deck by vertical suspender cables. The towers act as a substructure and resist the forces applied to the main cables.

Suspension bridges are relatively light and flexible, and they may sway and ripple with the wind or move when the ground shakes, both vertically and laterally. The challenge is to assure aerodynamic stability and minimize motion.

Cable-Stayed Bridges

Cable-stayed bridges also rely on cables to suspend the deck, but all of the nearly straight diagonal cables attach directly to the towers. The towers transfer the forces from the cables to the foundation through vertical compression.

As seen in the Millau Viaduct, these cables meet at the midpoint of two towers. Fewer towers are required to be constructed for this type of bridge than for a suspension bridge of the same length since the towers can be further apart.

The superstructure and substructure are rigidly connected as a single unit.

This can be handy for specific design requirements, such as a seemingly steep incline in the case of the Eshima Ohashi Bridge, which has a mere 6.1 gradient on one side and a 5.1 gradient on the other.

Movable Bridges

Lastly, there are movable bridges like the Tower Bridge. It features a drawbridge at its midpoint, allowing ships to pass through underneath. The two parts of the lower deck are counterbalanced by two movable sections weighing over one thousand tons each. It’s also a great example of a hybrid bridge since it’s also a suspension bridge.

All the different types of bridges show just how complex these structures can be, yet the possibilities are endless. There’s a bridge for every terrain and every unique purpose. They are truly a remarkable feat of engineering.

Conclusion

I could go on and on about all kinds of clever bridges, but basically, bridges are strong not only because they’re made of strong materials, but also because of the smart designs dreamed up and planned by engineers. So, thanks for asking, Hannah! And thank you for hanging out with us at SciShow Kids. See you next time!